Copyright © 2025 CRD Laser Technology Co., Ltd. All Rights Reserved

The application of CO2 laser in the automotive industry

The automotive industry uses a variety of materials, including plastics, composites, textiles, leather, glass and rubber. From the tiniest interior components to large pillars and bumpers, from Windows, windshields, wipers and door seals to seat belts and airbags, CO2 lasers can replace traditional tools throughout the manufacturing process to cut and mark these materials. Laser processes include cutting, drilling and marking. With the rapid development of electric vehicles, lasers are increasingly being used to assist in product development and manufacturing. Lasers are often combined with robot systems. Automated robot units can perform multiple tasks, thereby enhancing productivity. The laser system can ensure the consistency of product quality and a low scrap rate, and it also has the flexibility to quickly adapt to new designs.

1. Remove the glaze coating of the motor flat wire

The motor of an electric vehicle uses rectangular flat wires up to 6 millimeters wide with a glazed dielectric layer (PEEK, PFA-PI, PA) coated on the surface to ensure insulation. However, in practical applications, we need to remove this coating to facilitate the welding of the flat wires and achieve electrical contact. Unlike mechanical methods, laser processing is non-contact, with no copper erosion or loss, and almost no need to stop the machine or change any tools.

2. Laser removal of the insulation coating on the busbar

Busbars are made of metals, usually copper or aluminum, and are used for transmitting electricity in electric vehicles and connecting high-voltage or low-voltage devices in battery packs. They conduct a large amount of electricity and have an epoxy coating for insulation. The coating must be partially removed so that the busbar can be connected to other components in the vehicle. Unlike mechanical methods, laser ablation is non-contact, does not ablate or lose metal, and requires almost no downtime while keeping the metal intact.

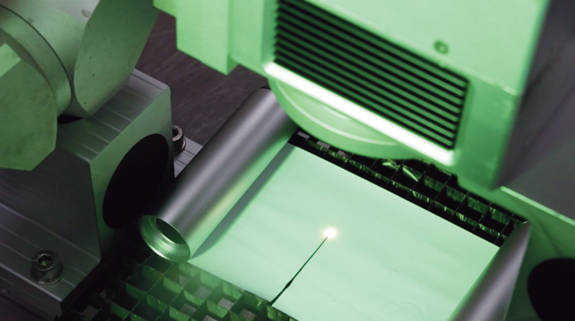

3. Laser cutting of battery separators

The diaphragm is made of plastic film with a thickness of less than 30 microns and is mainly cut to the required length by mechanical tools to prevent short circuits between the electrodes. The latest battery separator technology is to apply a thin ceramic coating on one side of the film. Cutting with a knife will increase the wear of the tool, and small ceramic particles will fall off from the cutting edge, causing dust contamination on the film. Laser technology is a non-contact processing method that can eliminate the dust brought by traditional processing methods. That is, there will be no tool wear and no damage to films and coatings.

LATEST NEWS

- The differences between RF CO2 laser and glass tube CO2 laser 2025-04-18 19:29:40

- The application of CO2 laser in the automotive industry 2025-05-30 18:38:01

- Applications of CO2 Lasers in the Electronics Industry 2025-05-22 19:29:36

- The application of CO2 laser in the glass and acrylic industry 2025-05-08 19:29:38

- The application of CO2 Laser in the medical aesthetics industry 2025-12-13 14:06:34