Copyright © 2025 CRD Laser Technology Co., Ltd. All Rights Reserved

Applications of CO2 Lasers in the Electronics Industry

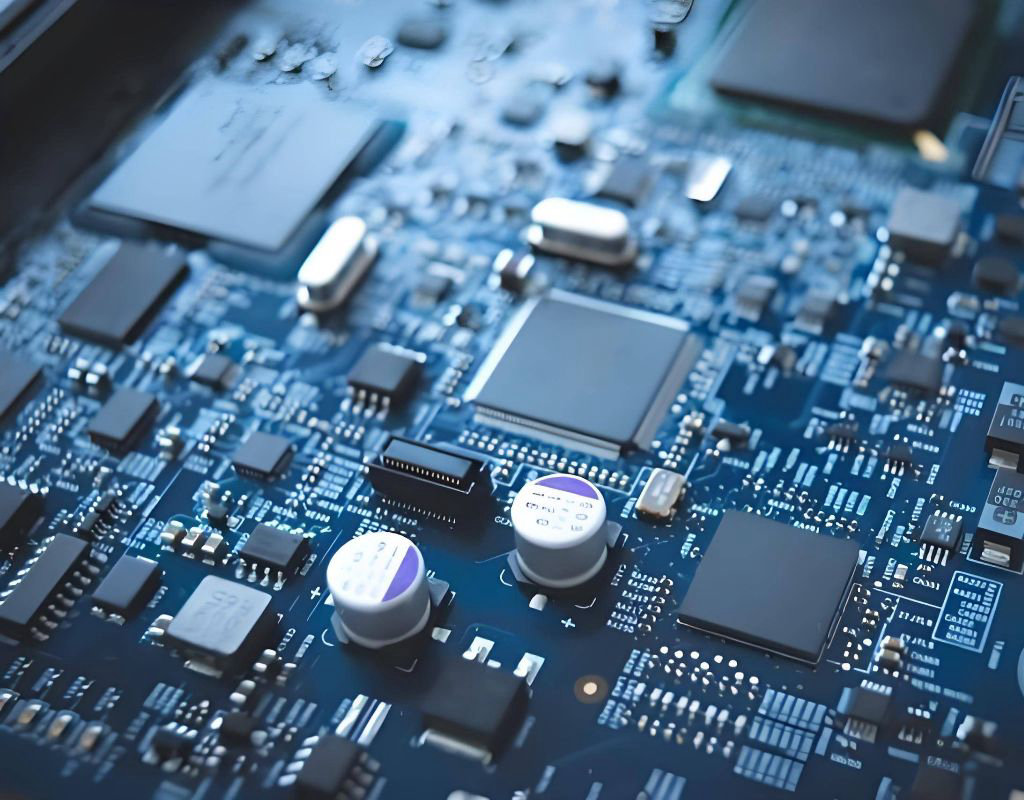

In the field of the electronics industry, multiple devices are usually manufactured simultaneously on a single substrate. Then cut the base material to separate the various components or circuits. The base material is usually ceramic or FR4 composite material, both of which can be cut by CO2 laser. The non-contact nature of the laser process minimizes the risk of damaging devices, reduces waste and increases output.

Other applications of CO2 lasers in the electronics industry include degreasing and micro-hole drilling of PCB boards, marking and cutting of ceramics, marking of electronic components, and pattern engraving on display light guide plates, etc.

1. Marking of PCB board and Electronic Components:

Lasers can be used to mark important information on various PCB boards and electronic components, including diodes, capacitors, transistors and IC chips. CO2 lasers can mark on various materials, including ceramics, plastics and composite materials. The mark is permanent and non-erasable. High-speed dynamic marking can be carried out on components during the production process on the production line, featuring high speed and high precision.

2. PCB Board Cutting:

While PCB circuit boards can be mechanically cut, this method generates a significant amount of dust and debris, and there is a risk of delamination in the composite substrate. Therefore, laser cutting presents an ideal solution. By selecting the appropriate cutting parameters, CO2 laser cutting can achieve results that are comparable to those produced by mechanical cutting, all while separating individual circuits without physical contact or induced stress.

3. Ceramic Cutting and Drilling:

Ceramics are widely used in the electronics industry, however, traditional machining methods pose challenges due to the material's hardness and brittleness, coupled with the typically small size of the components. Laser processing enables the creation of lines, grooves, holes, and intricate profiles without physical contact, thereby minimizing mechanical stress. Precise parameter control is essential when utilizing laser processing. The pulse characteristics of the laser are crucial, as longer pulses combined with slower processing speeds often yield exceptional results.

4. Ceramic Scribing:

Ceramics can be separated into components by drilling a series of closely spaced blind holes along the desired cutting line. Subsequently, the ceramic can cleanly fracture along this line. In many instances, this "scribing and breaking" technique proves to be faster and more reliable than conventional cutting methods. It is imperative to precisely control the depth and spacing of the holes to ensure complete fracture.

LATEST NEWS

- The differences between RF CO2 laser and glass tube CO2 laser 2025-04-18 19:29:40

- The application of CO2 laser in the automotive industry 2025-05-30 18:38:01

- Applications of CO2 Lasers in the Electronics Industry 2025-05-22 19:29:36

- The application of CO2 laser in the glass and acrylic industry 2025-05-08 19:29:38

- The application of CO2 Laser in the medical aesthetics industry 2025-12-13 14:06:34